Knowledge

Knowledge

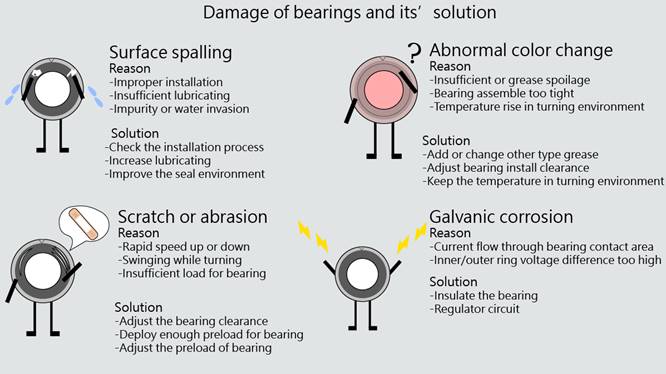

| Subject | Damage of bearings and its’solution |

|---|---|

| Date | 2021/7/29 |

| Content |

Damage of bearings and its’ solution In usual usage situation, bearing can rotate for thousands of hours, however, there are many factors can cause different kinds of damage or abnormal situation, the following article will introduce common damage situation and improve method. 1. Surface spalling Flake surface spalling on bearing inner or outer ring, which may cause from -Improper installation -Insufficient lubricating or using wrong grease -Too much load while bearing rotating -Impurity or water invasion Improve method -Check the installation process -Increase lubricating or replace the grease -Improve the seal environment, also clean up while stop turning 2. Scratch or abrasion Light mark on the surface or surface get rough, which happen on the race surface or rolling surface, which may cause from -Rapid speed up or down -Swinging while turning -Insufficient load for bearing Improve method -Adjust the bearing clearance -Deploy enough preload for bearing -Adjust the preload of bearing 3.Abnormal color change Unusual color change on bearing rolling elements or bearing cage, which may cause from -Insufficient or grease spoilage -Bearing assemble too tight -Temperature rise in turning environment Improve method -Add or change other type grease -Adjust bearing install clearance -Keep the temperature in turning environment 4. Galvanic corrosion Due to the current flow, cause temperature rising, led to the sunken on the inner, outer ring or rolling element, which may case from -Current flow through bearing contact area -Inner and outer ring voltage difference too high Improve method -Insulate the bearing -Regulator circuit -Using insulation bearing

|