Knowledge

Knowledge

| Subject | Grease of bearing |

|---|---|

| Date | 2021/10/15 |

| Content |

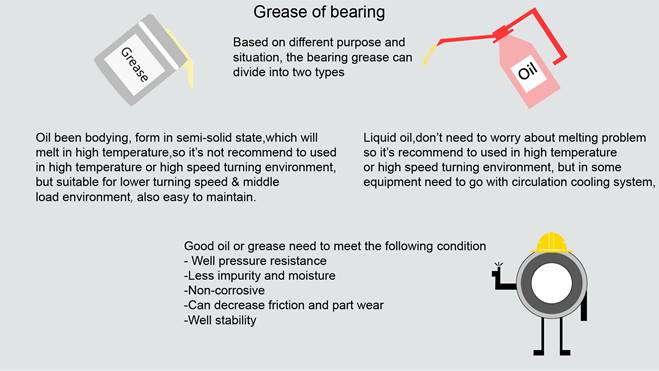

Grease of bearings Most bearings need grease to keep turning, except oilless bearing, through grease, not only decrease friction, but can achieve the following effect. 1. Form grease film on the rolling surface, extend rating life of bearing, but if the grease film is too thin, the rating life will decrease. 2. Discharge the heat from inner friction and outer turning, cam avoid the temperature let the grease spoilage. Based on different purpose and situation, the bearing grease can divide into two types 1. Grease Here the grease means the oil been bodying, form in semi-solid state, cause semi-solid state will melt in high temperature, so it’s not recommend to used in high temperature or high speed turning environment, may cause oil spill. Generally, grease is suitable for lower turning speed & middle load environment, the higher turning speed will need less grease, though grease isn’t flexible as oil, but it’s easier to maintain.

2. Oil Here the oil means liquid oil, different from grease, don’t need to worry about melting problem, so it’s recommend to used in high temperature or high speed turning environment, but there’s recommend using temperature for different oil, so still need to pay attention to turning temperature, also, in some equipment need to go with circulation cooling system, avoid the oil spoilage. Generally, oil is suitable for high speed and high load environment. How to choose good grease and oil? Good oil or grease need to meet the following condition - Well pressure resistance -Less impurity and moisture -Non-corrosive -Can decrease friction and part wear -Well stability

|